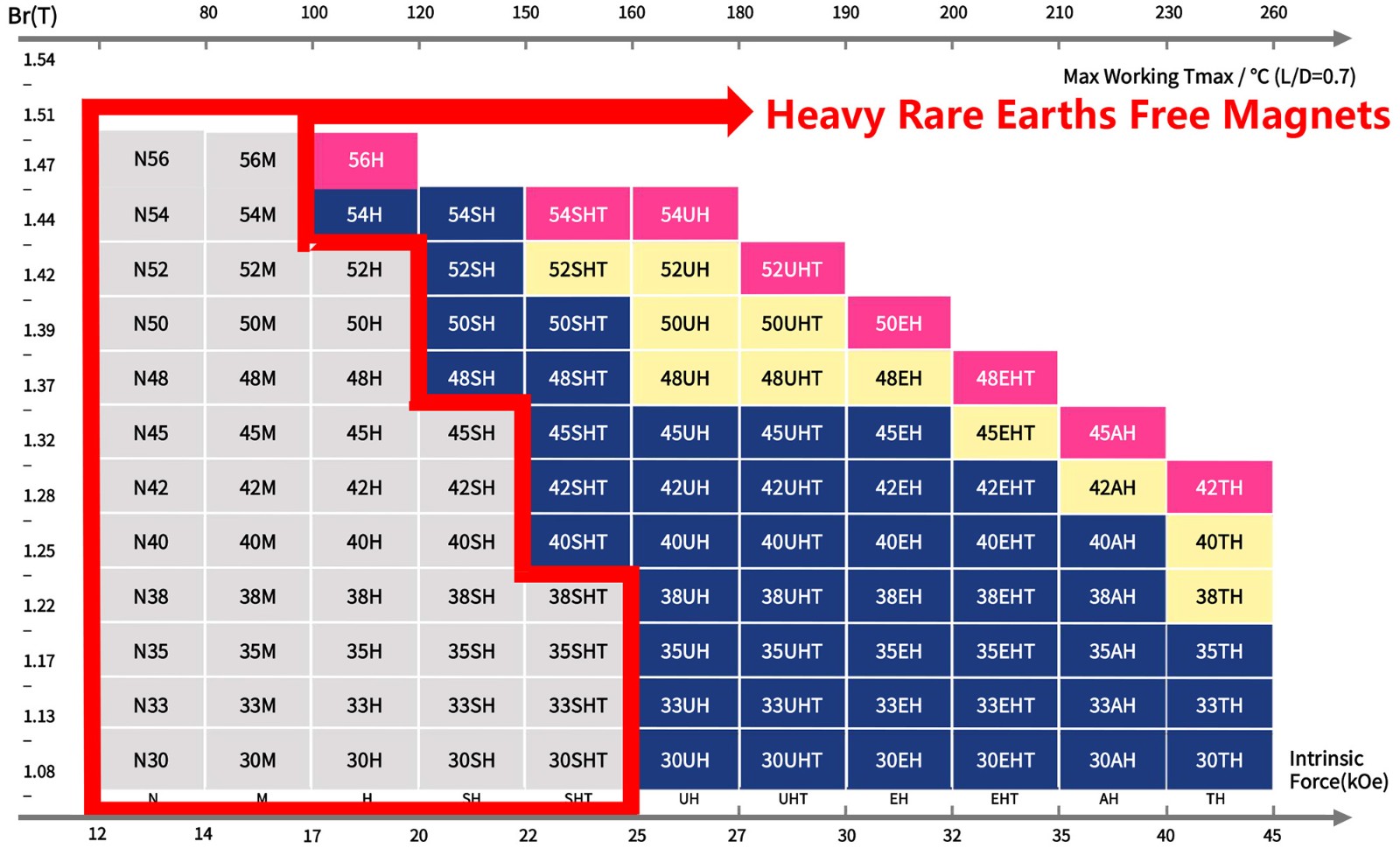

Magnet Grades

-

Dysprosium (Dy) or Terbium (Tb) Free

-

Regular +GBD

-

GBD only

-

Laboratory phase

NdFeB Performance Parameter Table

| Series |

Parameter Unit Grade |

Remanence | Intrinic Coercivity | Coercivity | Max Energy Product | Density |

Relative Recoil Permeability |

Temperature Coeffcient |

Max Working Temperature |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | αBr | αHcj |

℃ (L/D=0 .7) |

|||||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | Min | %/℃ | %/℃ | ||||

| N | N56 | 1.50 | 1.46 | 15.0 | 14.6 | 876 | 11 | 812 | 10.2 | 446 | 406 | 56 | 51 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N54 | 1.48 | 1.44 | 14.8 | 14.4 | 955 | 12 | 892 | 11.2 | 438 | 398 | 55 | 50 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| N52 | 1.46 | 1.42 | 14.6 | 14.2 | 955 | 12 | 892 | 11.2 | 422 | 390 | 53 | 49 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| N50 | 1.44 | 1.39 | 14.4 | 13.9 | 955 | 12 | 892 | 11.2 | 406 | 374 | 51 | 47 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| N48 | 1.42 | 1.37 | 14.2 | 13.7 | 955 | 12 | 892 | 11.2 | 390 | 358 | 49 | 45 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| N45 | 1.37 | 1.32 | 13.7 | 13.2 | 955 | 12 | 892 | 11.2 | 366 | 342 | 46 | 43 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| N42 | 1.32 | 1.28 | 13.2 | 12.8 | 955 | 12 | 923 | 11.6 | 342 | 318 | 43 | 40 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| N40 | 1.28 | 1.25 | 12.8 | 12.5 | 955 | 12 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| N38 | 1.25 | 1.22 | 12.5 | 12.3 | 955 | 12 | 923 | 11.6 | 310 | 287 | 39 | 36 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| N35 | 1.22 | 1.17 | 12.2 | 11.7 | 955 | 12 | 923 | 11.6 | 287 | 263 | 36 | 33 | 7.50 | 1.05 | -0.12 | -0.76 | 80 | |

| M | N54M | 1.49 | 1.44 | 14.9 | 14.4 | 1114 | 14 | 1035 | 13.0 | 438 | 398 | 55 | 50 | 7.50 | 1.05 | -0.12 | -0.76 | 100 |

| N52M | 1.46 | 1.42 | 14.6 | 14.2 | 1114 | 14 | 1035 | 13.0 | 422 | 390 | 53 | 49 | 7.50 | 1.05 | -0.12 | -0.68 | 100 | |

| N50M | 1.44 | 1.39 | 14.4 | 13.9 | 1114 | 14 | 1035 | 13.0 | 406 | 374 | 51 | 47 | 7.50 | 1.05 | -0.12 | -0.68 | 100 | |

| N48M | 1.42 | 1.37 | 14.2 | 13.7 | 1114 | 14 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.50 | 1.05 | -0.12 | -0.68 | 100 | |

| N45M | 1.37 | 1.32 | 13.7 | 13.2 | 1114 | 14 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.50 | 1.05 | -0.12 | -0.68 | 100 | |

| N42M | 1.32 | 1.28 | 13.2 | 12.8 | 1114 | 14 | 955 | 12.0 | 342 | 318 | 43 | 40 | 7.50 | 1.05 | -0.12 | -0.68 | 100 | |

| N40M | 1.28 | 1.25 | 12.8 | 12.5 | 1114 | 14 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.50 | 1.05 | -0.12 | -0.68 | 100 | |

| N38M | 1.25 | 1.22 | 12.5 | 12.3 | 1114 | 14 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.50 | 1.05 | -0.12 | -0.68 | 100 | |

| N35M | 1.22 | 1.17 | 12.2 | 11.7 | 1114 | 14 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.50 | 1.05 | -0.12 | -0.68 | 100 | |

| H | N54H | 1.49 | 1.44 | 14.9 | 14.4 | 1353 | 17 | 1083 | 13.6 | 438 | 398 | 55 | 50 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| N52H | 1.46 | 1.42 | 14.6 | 14.2 | 1353 | 17 | 1067 | 13.4 | 422 | 390 | 53 | 49 | 7.50 | 1.05 | -0.12 | -0.66 | 120 | |

| N50H | 1.44 | 1.39 | 14.4 | 13.9 | 1353 | 17 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.50 | 1.05 | -0.12 | -0.66 | 120 | |

| N48H | 1.42 | 1.37 | 14.2 | 13.7 | 1353 | 17 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.50 | 1.05 | -0.12 | -0.66 | 120 | |

| N45H | 1.37 | 1.32 | 13.7 | 13.2 | 1353 | 17 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.50 | 1.05 | -0.12 | -0.66 | 120 | |

| N42H | 1.32 | 1.28 | 13.2 | 12.8 | 1353 | 17 | 955 | 12.0 | 342 | 318 | 43 | 40 | 7.50 | 1.05 | -0.12 | -0.66 | 120 | |

| N40H | 1.28 | 1.25 | 12.8 | 12.5 | 1353 | 17 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.50 | 1.05 | -0.12 | -0.66 | 120 | |

| N38H | 1.25 | 1.22 | 12.5 | 12.3 | 1353 | 17 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.50 | 1.05 | -0.12 | -0.66 | 120 | |

| N35H | 1.22 | 1.17 | 12.2 | 11.7 | 1353 | 17 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.50 | 1.05 | -0.12 | -0.66 | 120 | |

| SH | N54SH | 1.49 | 1.44 | 14.9 | 14.4 | 1592 | 20 | 1083 | 13.6 | 438 | 398 | 55 | 50 | 7.50 | 1.04 | -0.12 | -0.66 | 150 |

| N52SH | 1.46 | 1.41 | 14.6 | 14.1 | 1592 | 20 | 1059 | 13.3 | 414 | 382 | 52 | 48 | 7.50 | 1.04 | -0.12 | -0.66 | 150 | |

| N50SH | 1.44 | 1.39 | 14.4 | 13.9 | 1592 | 20 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.50 | 1.04 | -0.12 | -0.66 | 150 | |

| N48SH | 1.42 | 1.37 | 14.0 | 13.7 | 1592 | 20 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.50 | 1.04 | -0.11 | -0.56 | 150 | |

| N45SH | 1.37 | 1.32 | 13.7 | 13.2 | 1592 | 20 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.50 | 1.04 | -0.11 | -0.56 | 150 | |

| N42SH | 1.32 | 1.28 | 13.2 | 12.8 | 1592 | 20 | 963 | 12.1 | 342 | 318 | 43 | 40 | 7.50 | 1.04 | -0.11 | -0.56 | 150 | |

| N40SH | 1.28 | 1.25 | 12.8 | 12.5 | 1592 | 20 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.50 | 1.04 | -0.11 | -0.56 | 150 | |

| N38SH | 1.25 | 1.22 | 12.5 | 12.2 | 1592 | 20 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.50 | 1.04 | -0.11 | -0.56 | 150 | |

| N35SH | 1.22 | 1.17 | 12.2 | 11.7 | 1592 | 20 | 884 | 11.1 | 295 | 263 | 37 | 33 | 7.50 | 1.04 | -0.11 | -0.56 | 150 | |

| N33SH | 1.17 | 1.13 | 11.7 | 11.3 | 1592 | 20 | 844 | 10.6 | 271 | 247 | 34 | 31 | 7.50 | 1.04 | -0.11 | -0.56 | 150 | |

| N30SH | 1.13 | 1.08 | 11.3 | 10.8 | 1592 | 20 | 804 | 10.1 | 247 | 223 | 31 | 28 | 7.50 | 1.04 | -0.11 | -0.56 | 150 | |

| UH | N54UH | 1.49 | 1.44 | 14.9 | 14.4 | 1990 | 25 | 1083 | 13.6 | 438 | 398 | 55 | 50 | 7.50 | 1.03 | -0.11 | -0.50 | 180 |

| N52UH | 1.46 | 1.42 | 14.6 | 14.2 | 1990 | 25 | 1067 | 13.4 | 422 | 390 | 53 | 49 | 7.50 | 1.03 | -0.11 | -0.50 | 180 | |

| N50UH | 1.42 | 1.39 | 14.2 | 13.9 | 1990 | 25 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.50 | 1.03 | -0.11 | -0.50 | 180 | |

| N48UH | 1.40 | 1.36 | 14.0 | 13.6 | 1990 | 25 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.55 | 1.03 | -0.11 | -0.50 | 180 | |

| N45UH | 1.36 | 1.32 | 13.6 | 13.2 | 1990 | 25 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.55 | 1.03 | -0.11 | -0.50 | 180 | |

| N42UH | 1.32 | 1.28 | 13.2 | 12.8 | 1990 | 25 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.55 | 1.03 | -0.10 | -0.50 | 180 | |

| N40UH | 1.28 | 1.25 | 12.8 | 12.5 | 1990 | 25 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.55 | 1.03 | -0.10 | -0.50 | 180 | |

| N38UH | 1.25 | 1.22 | 12.5 | 12.2 | 1990 | 25 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.55 | 1.03 | -0.10 | -0.50 | 180 | |

| N35UH | 1.22 | 1.17 | 12.2 | 11.7 | 1990 | 25 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.55 | 1.03 | -0.10 | -0.50 | 180 | |

| N33UH | 1.17 | 1.13 | 11.7 | 11.3 | 1990 | 25 | 852 | 10.7 | 271 | 247 | 34 | 31 | 7.55 | 1.03 | -0.10 | -0.50 | 180 | |

| N30UH | 1.13 | 1.08 | 11.3 | 10.8 | 1990 | 25 | 812 | 10.2 | 247 | 223 | 31 | 28 | 7.55 | 1.03 | -0.10 | -0.50 | 180 | |

| EH | N48EH | 1.40 | 1.36 | 14.0 | 13.6 | 2388 | 30 | 1051 | 13.2 | 390 | 358 | 49 | 45 | 7.60 | .03 | -0.10 | -0.45 | 200 |

| N45EH | 1.36 | 1.32 | 13.6 | 13.2 | 2388 | 30 | 1031 | 12.9 | 366 | 342 | 46 | 43 | 7.60 | 1.03 | -0.10 | -0.45 | 200 | |

| N42EH | 1.32 | 1.28 | 13.2 | 12.8 | 2388 | 30 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.60 | 1.03 | -0.10 | -0.45 | 200 | |

| N40EH | 1.28 | 1.25 | 12.8 | 12.5 | 2388 | 30 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.60 | 1.03 | -0.10 | -0.45 | 200 | |

| N38EH | 1.25 | 1.22 | 12.5 | 12.2 | 2388 | 30 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.45 | 200 | |

| N35EH | 1.22 | 1.17 | 12.2 | 11.7 | 2388 | 30 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.45 | 200 | |

| N33EH | 1.17 | 1.13 | 11.7 | 11.3 | 2388 | 30 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.45 | 200 | |

| N30EH | 1.13 | 1.08 | 11.3 | 10.8 | 2388 | 30 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.60 | 1.03 | -0.10 | -0.45 | 200 | |

| AH | N45AH | 1.36 | 1.32 | 13.6 | 13.2 | 2786 | 35 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| N42AH | 1.32 | 1.28 | 13.2 | 12.8 | 2786 | 35 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.60 | 1.03 | -0.10 | -0.45 | 230 | |

| N40AH | 1.28 | 1.25 | 12.8 | 12.5 | 2786 | 35 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.60 | 1.03 | -0.10 | -0.45 | 230 | |

| N38AH | 1.25 | 1.22 | 12.5 | 12.2 | 2786 | 35 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.45 | 230 | |

| N35AH | 1.20 | 1.17 | 12.0 | 11.7 | 2786 | 35 | 883 | 11.1 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.45 | 230 | |

| N33AH | 1.17 | 1.11 | 11.7 | 11.1 | 2786 | 35 | 844 | 10.6 | 271 | 239 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.45 | 230 | |

| N30AH | 1.13 | 1.07 | 11.3 | 10.7 | 2786 | 35 | 812 | 10.2 | 247 | 215 | 31 | 27 | 7.60 | 1.03 | -0.10 | -0.45 | 230 | |

(1) The temperature ranges for calculating the temperature coefficient are divided as follows: H grade and below, ΔT: 20–100°C; SH grade and above, ΔT: 20–150°C. The temperature coefficient is for reference only; for detailed demagnetization curves please contact our sales staff.

(2) The maximum operating temperature refers to the highest temperature at which the flux loss is ≤5% after the following condition: a standard cylindrical sample Ø10×7 mm (or one with diameter D and height L such that L/D = 0.7) is heated in open-circuit at high temperature for 2 hours and then returned to room temperature, comparing the flux after heating to the flux at room temperature before heating.

Production Processes

-

01

Proportioning

-

02

Strip casting

-

03

Hydrogen decrepitation

-

04

Powdering

-

05

Molding & Pressing

-

06

Sintering & Annealing

-

07

Inspection

-

08

Cutting/Machining

-

09

Surface treatment

-

10

Magnetization & Packaging

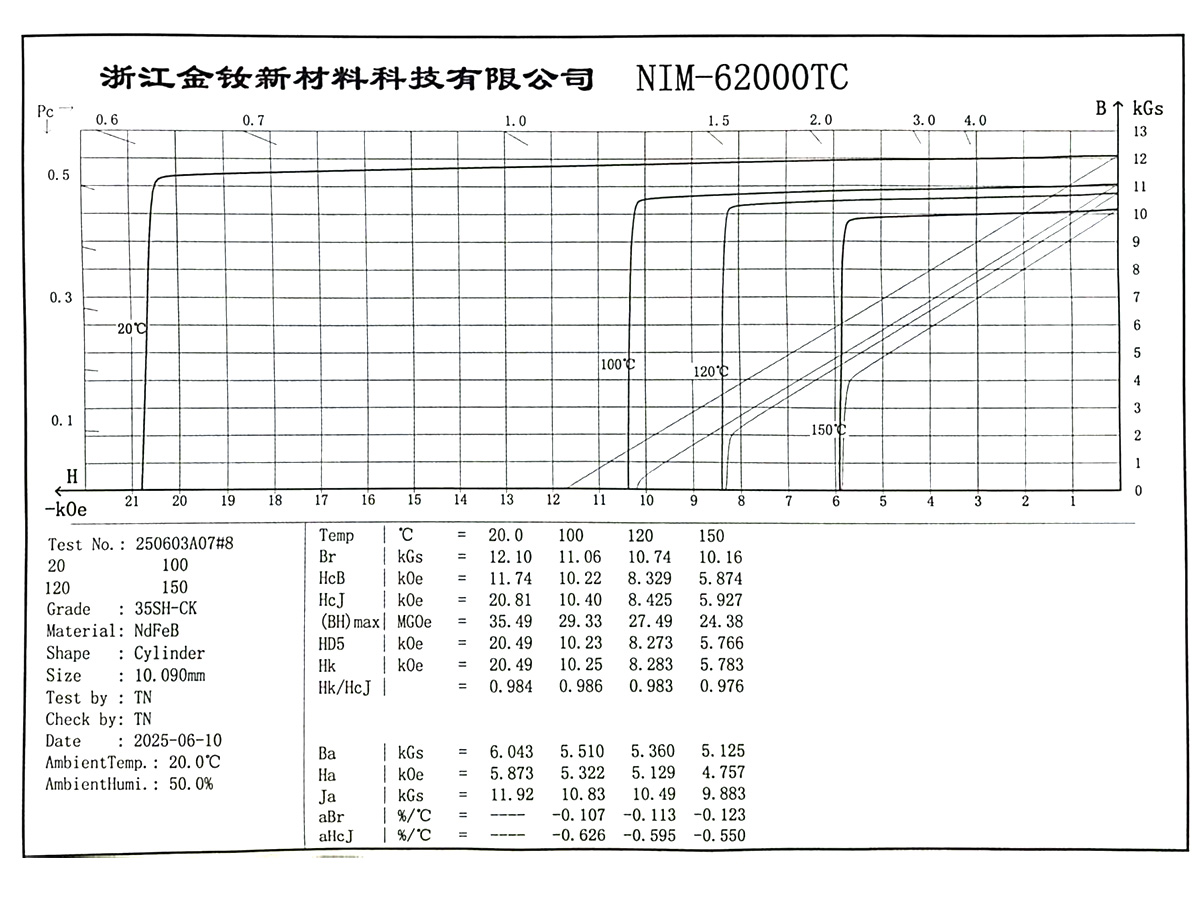

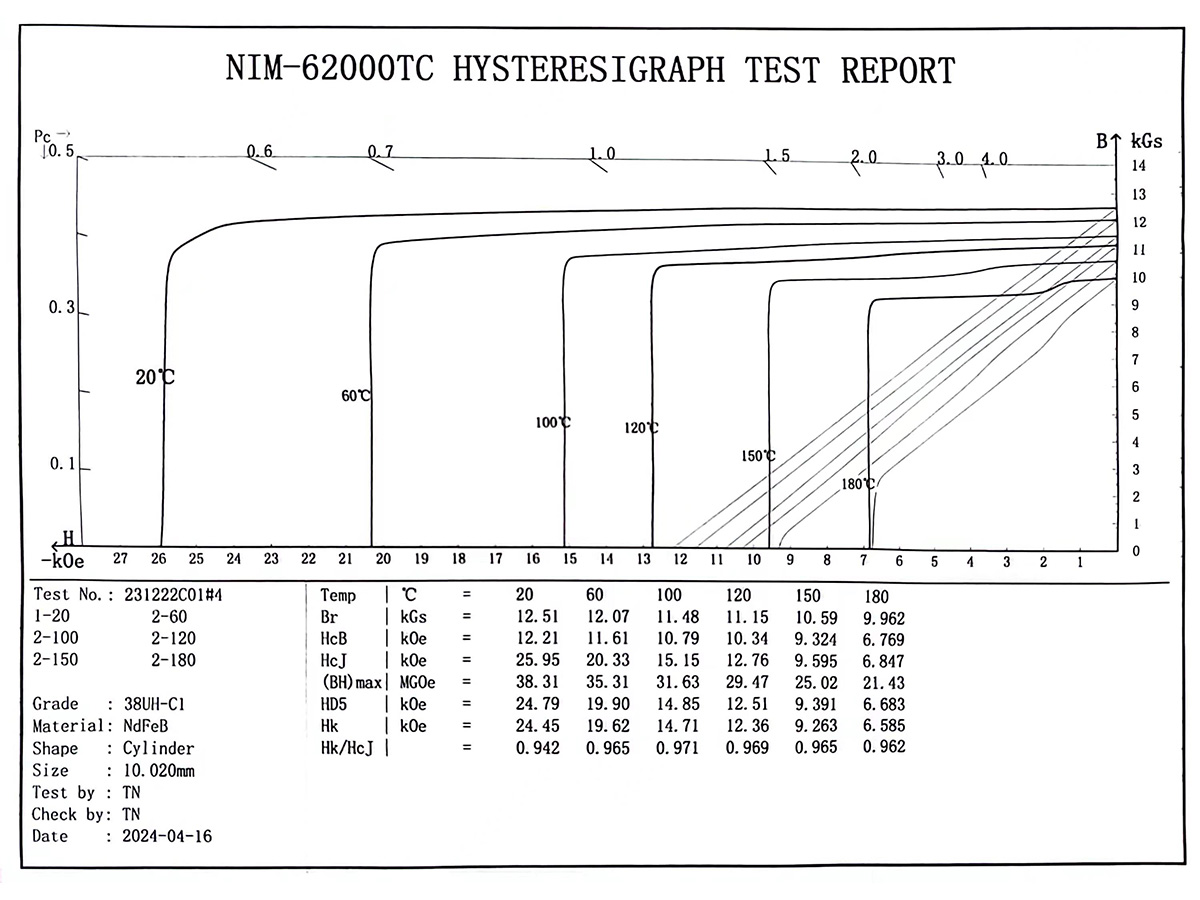

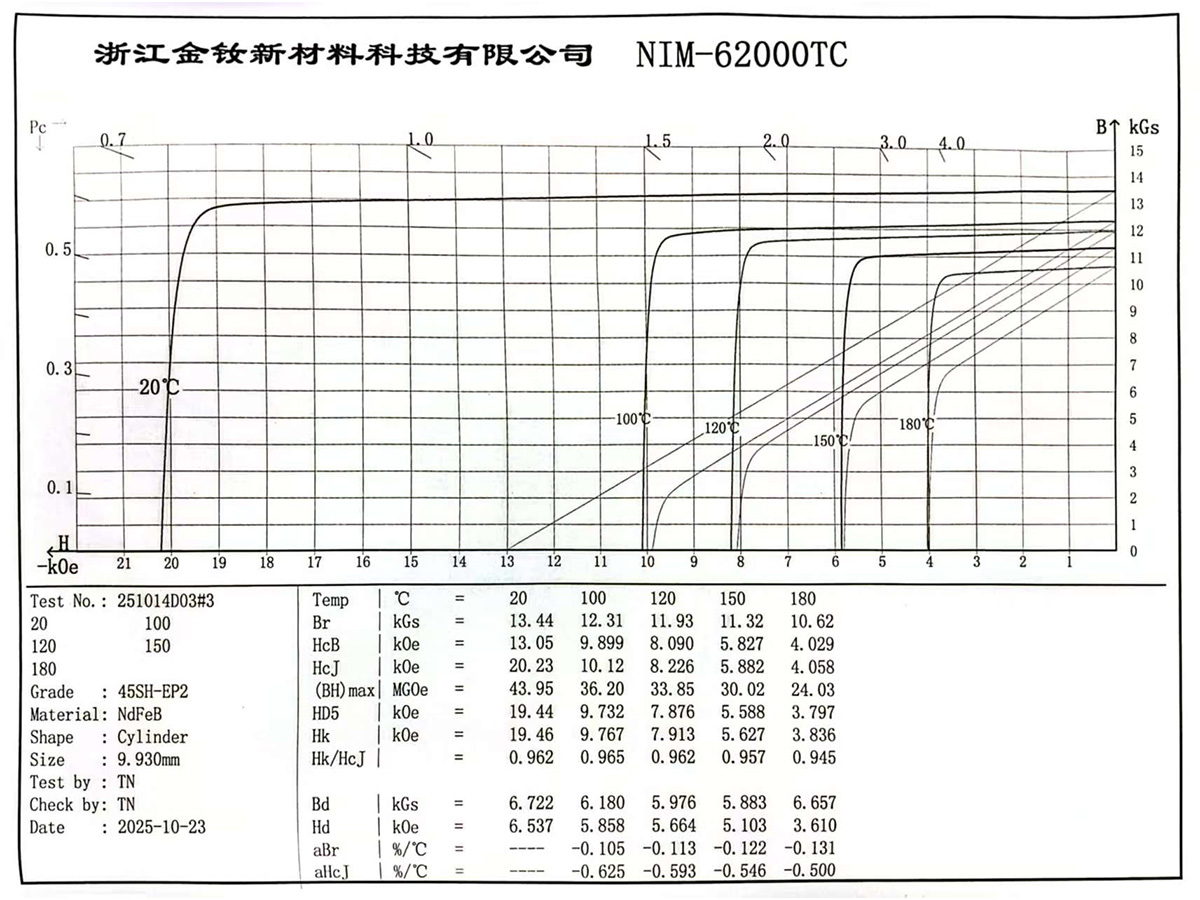

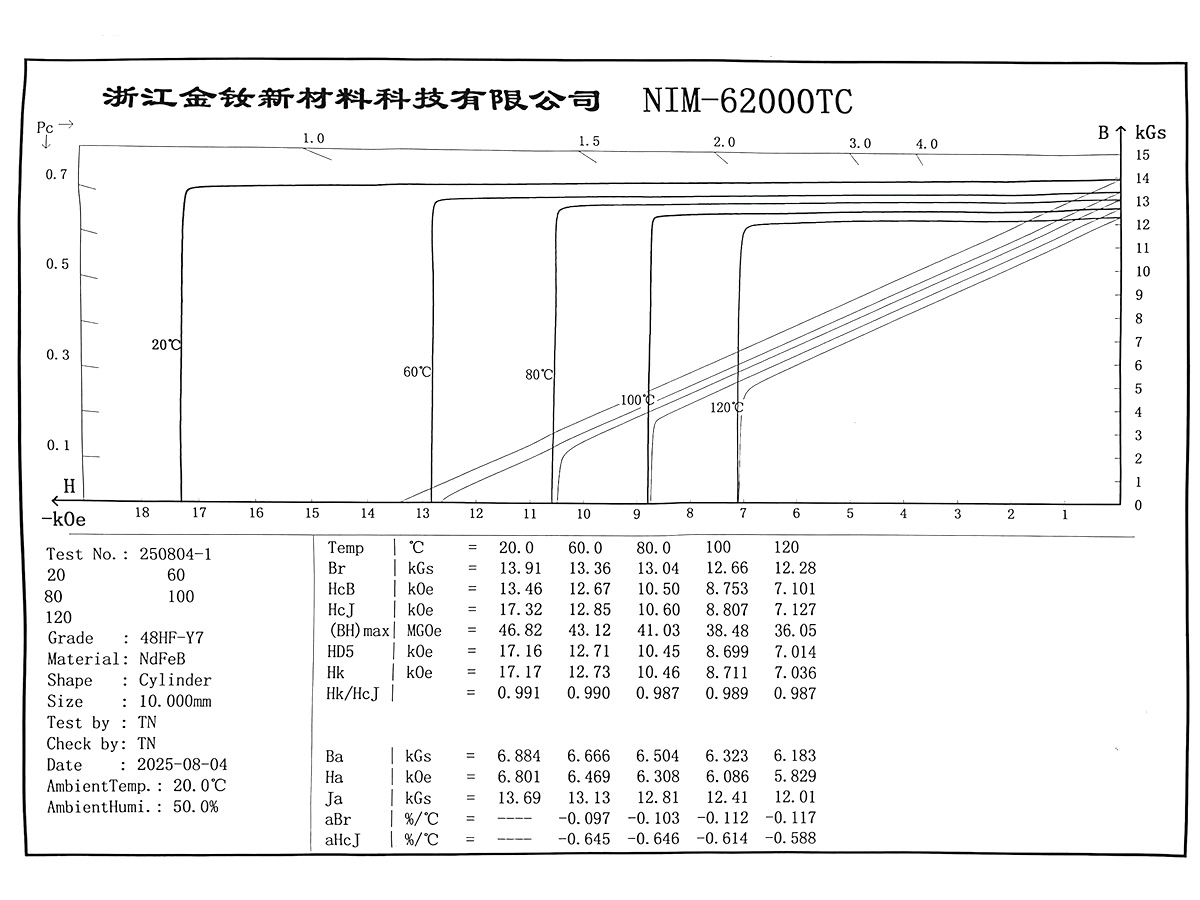

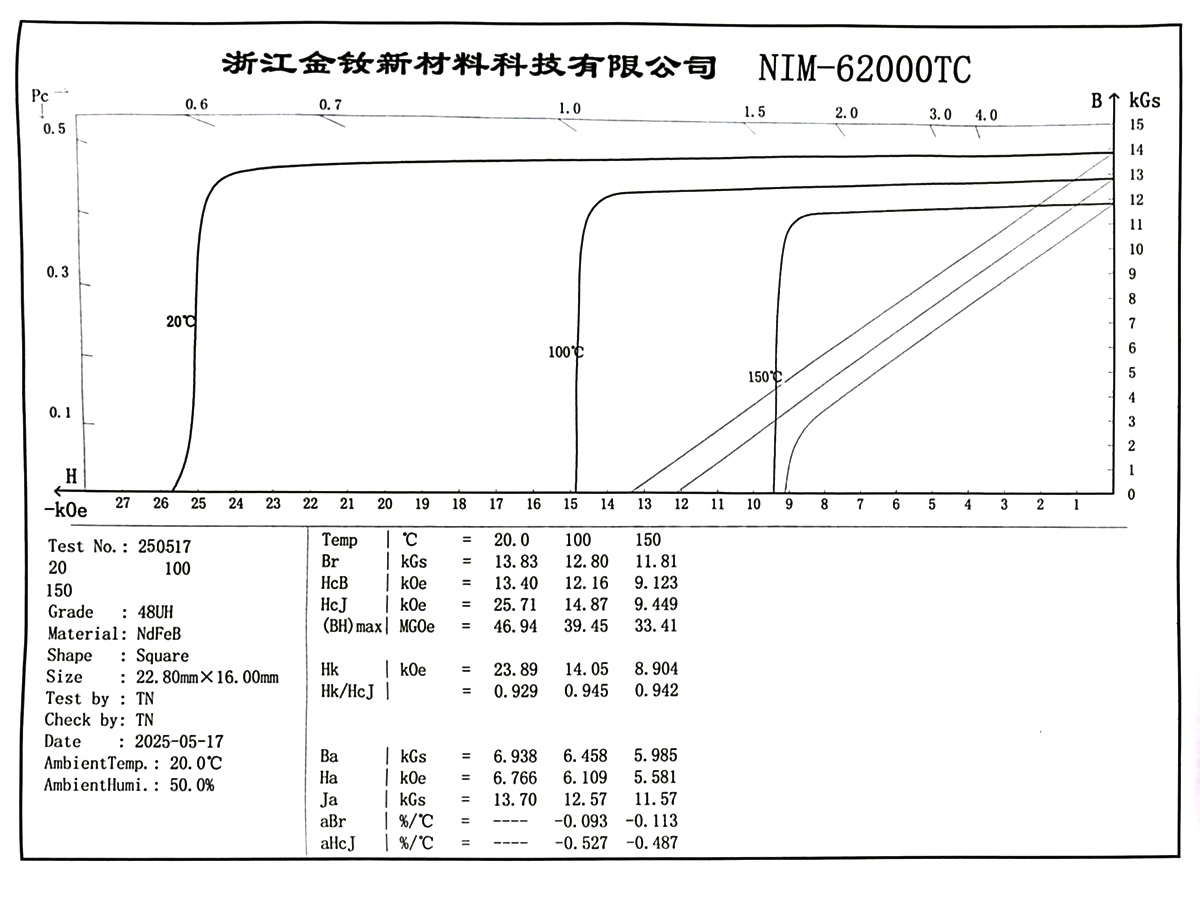

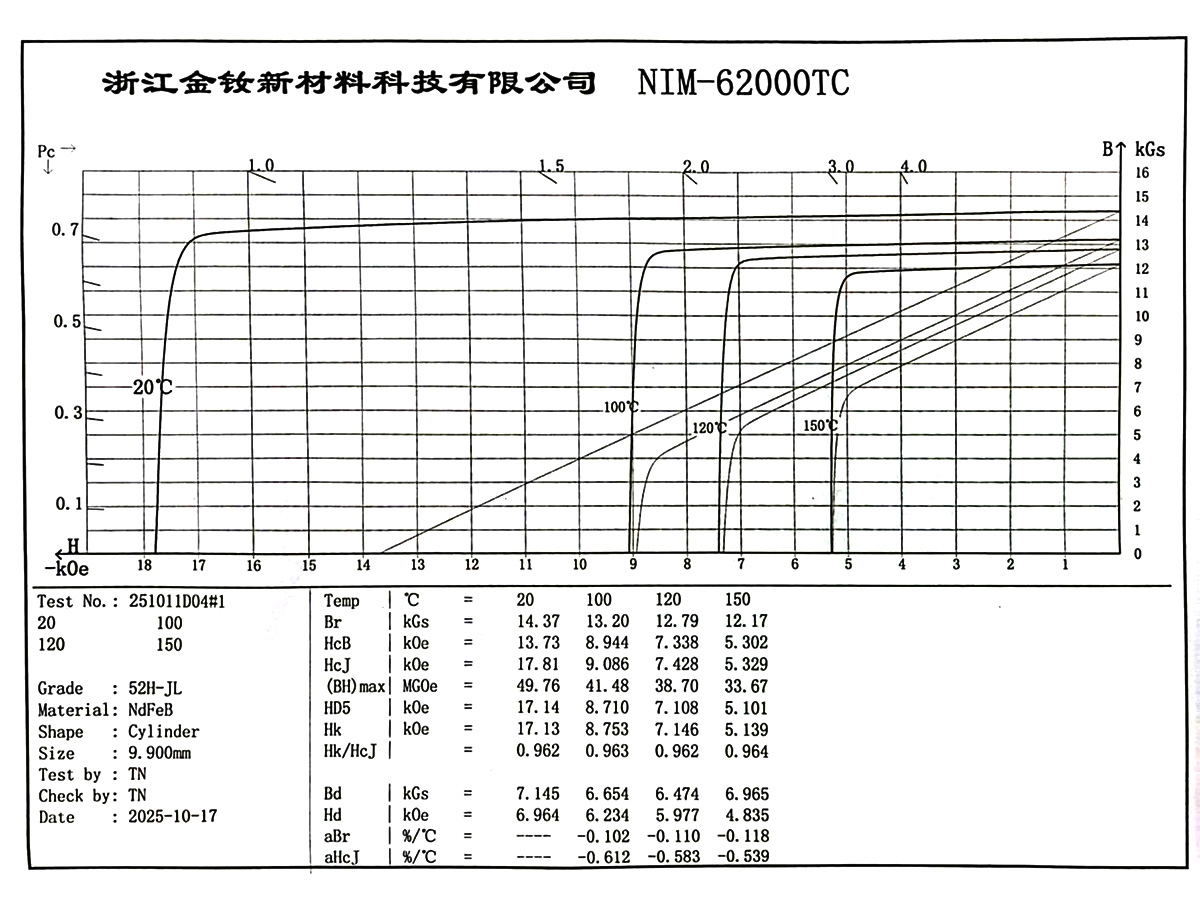

NdFeB Demagnetization Curve

-

35SH

-

38UH

-

45SH

-

48H

-

48UH

-

52H

Electroplating Capabilities

| Plating Type | Plating Symbol | Color | Plating Thickness (μm) | Plating Surface Protection Capability Comparison | Recommended operating temperature (°C) | ||

|---|---|---|---|---|---|---|---|

| Neutral Salt Spray Test | Humid Heat Test | Pressure Test (PCT) | |||||

| Nickel/Barrel Plating | Ni | Bright Silver | 10 - 20 | ★★★★★ | ★★★★★ | ★★★★★ | ≤200 |

| Nickel/Hanger Plating | Ni | Bright Silver | 10 - 20 | ★★★★ | ★★★★★ | ★★★★★ | - |

| Trivalent Chromium Zinc/Blue-White Zinc/Barrel Plating | Zn | Blue-White | 5 - 10 | ★★★★ | ★★★ | ★★★ | ≤160 |

| Trivalent Chromium Zinc/Blue-White Zinc/Hanger Plating | Zn | Blue-White | 5 - 10 | ★★★ | ★★★ | ★★★ | - |

| Trivalent Chromium Color Zinc/Barrel Plating | Color Zn | Bright Color | 5 - 10 | ★★★ | - | ★★★ | - |

| Trivalent Chromium Color Zinc/Hanger Plating | Color Zn | Bright Color | 5 - 10 | ★★★ | - | ★★★ | - |

| Nickel + Electroless Nickel/Barrel Plating | Ni + Chemical Ni | Dark Silver | 12 - 20 | ★★★★★ | ★★★★★ | ★★★★ | ≤200 |

| Nickel + Electroless Nickel/Hanger Plating | Ni + Chemical Ni | Dark Silver | 12 - 20 | ★★★★ | ★★★★★ | ★★★★ | - |

| Nickel + Chromium | Ni + Cr | Dark Black | 12 - 20 | ★★★★ | ★★★★★ | ★★★★★ | ≤200 |

| Teflon | Teflon | Black-Gray | - | ★★★ | ★★★ | ★★★ | ≤200 |

| Nickel + Black Nickel + Extra Black Nickel | Ni + Black Ni | Black | 12 - 20 | ★★★★★ | ★★★★★ | ★★★★★ | - |

| Nickel + Tin | Ni + Sn | Bright Silver | 12 - 20 | ★★★★ | ★★★★★ | ★★★★★ | - |

| Nickel + Silver | Ni + Ag | Silver | 12 - 20 | ★★★★ | ★★★★★ | ★★★★★ | - |

| Nickel + Gold | Ni + Au | Gold | 10 - 20 | ★★★★ | ★★★★★ | ★★★★★ | - |

| Epoxy Resin | EPOXY | Black | 10 - 20 | ★★★★★ | ★★★★★ | ★★★★ | ≤130 |

| Copper-Nickel Plating/Copper Plating + Epoxy Resin | POXY | Black | 15 - 25 | ★★★★★ | ★★★★ | ★★★ | ≤120 |

| Phosphatization/Passivation | phosphatization/Passivation | <Black-Gray | 1 - 3 | —— | —— | —— | ≤240 |

| Nano Coating | Nano coating | Bright Gray | 20 - 30 | ★★★★★★★ | ★★★★★★★ | ★★★★★★★★ | ≤350 |